Medical Paper-Film Pouch

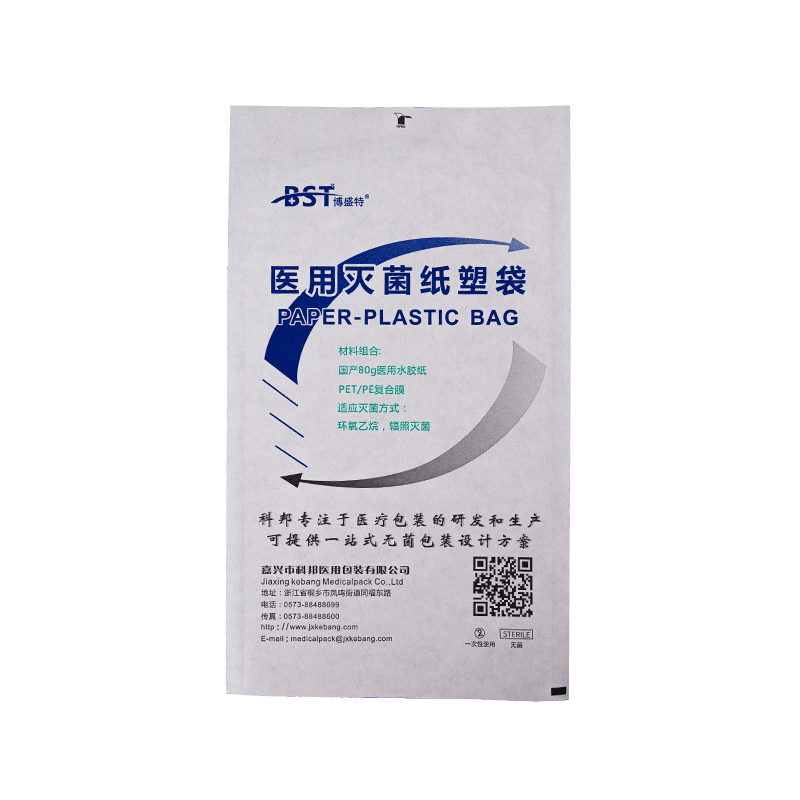

A

Material composition: imported/domestic medical glue paper (60g, 70g, 80g/m2) + PET/PE medical composite film

Features:

1. Good antibacterial properties and breathability;

2. Printed with environmentally friendly water-based ink, non-toxic;

3. It has good heat sealing and peeling performance, making it easy to take out and use the instrument;

4. The product is valid for up to 5 years;

Sterilization form: suitable for ethylene oxide and radiation sterilization;

Implementation standards: ISO 11607, EN 868, YY/T 0698-7

Applicable: Widely used, mostly used in Class I and Class II products, such as: surgical gloves, catheters, gauze, syringes, scalpels and other medical equipment sterilization packaging;

Product specifications: Can be customized according to customer requirements.

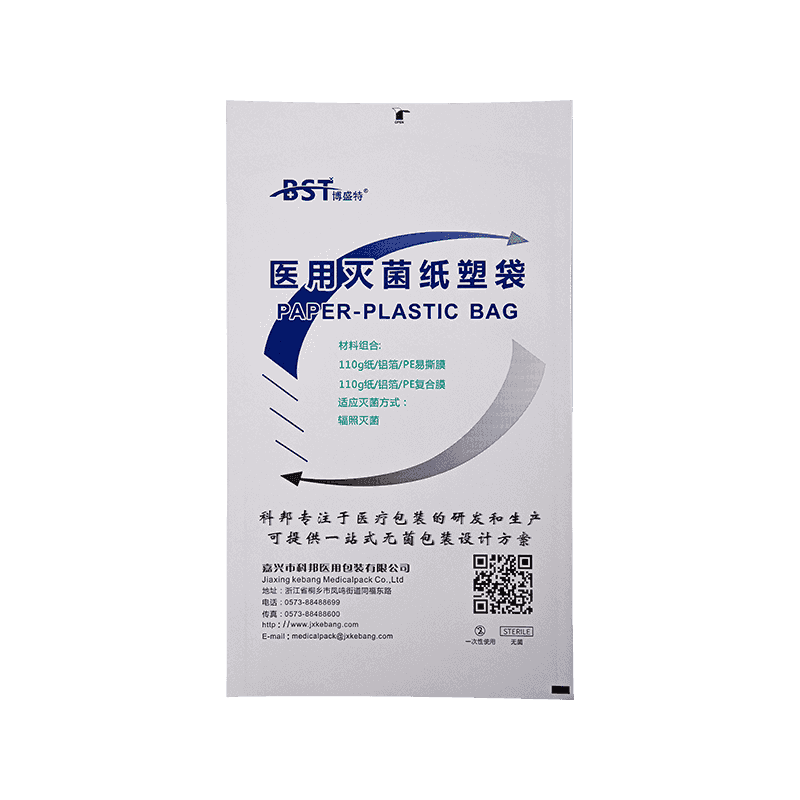

B

Material composition: imported/domestic medical self-adhesive paper (60g, 70g/m2) + PET/CPP medical composite film

Features:

1. Good antibacterial properties and breathability

2. Printed with environmentally friendly water-based ink, non-toxic

3. It has good heat sealing and peeling performance, making it easy to take out and use the instrument.

4. The product is valid for more than 6 months

Sterilization form: suitable for sterilization by ethylene oxide, high temperature steam, formaldehyde, etc.

Implementation standards: ISO 11607, EN 868, YY/T 0698-5

Applicable: Widely used, mostly used in Class I and Class II products, such as: surgical gloves, catheters, gauze, syringes and other medical equipment sterilization packaging

Product specifications: Can be customized according to customer requirements

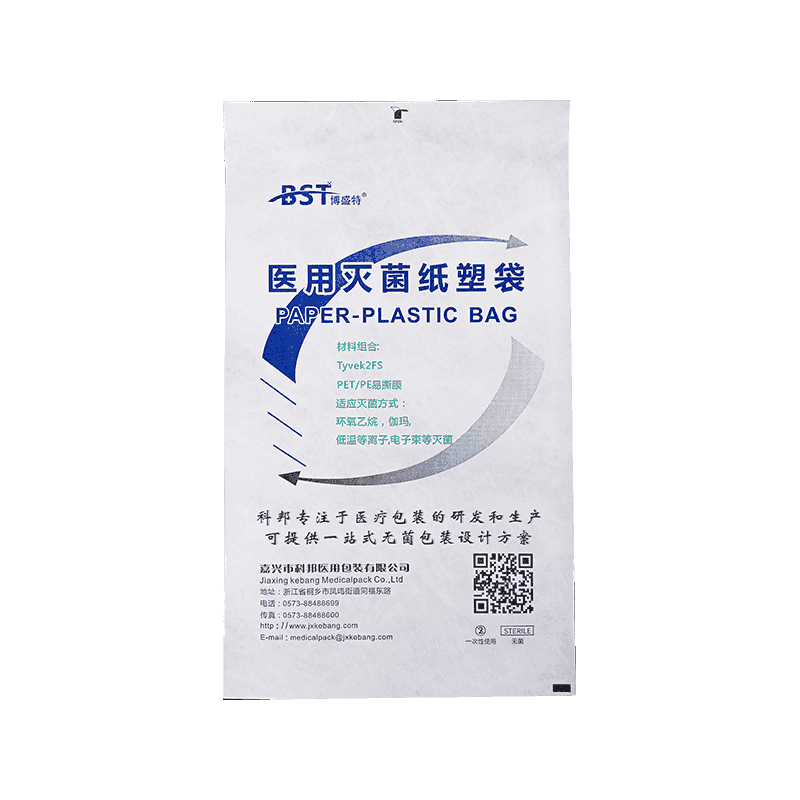

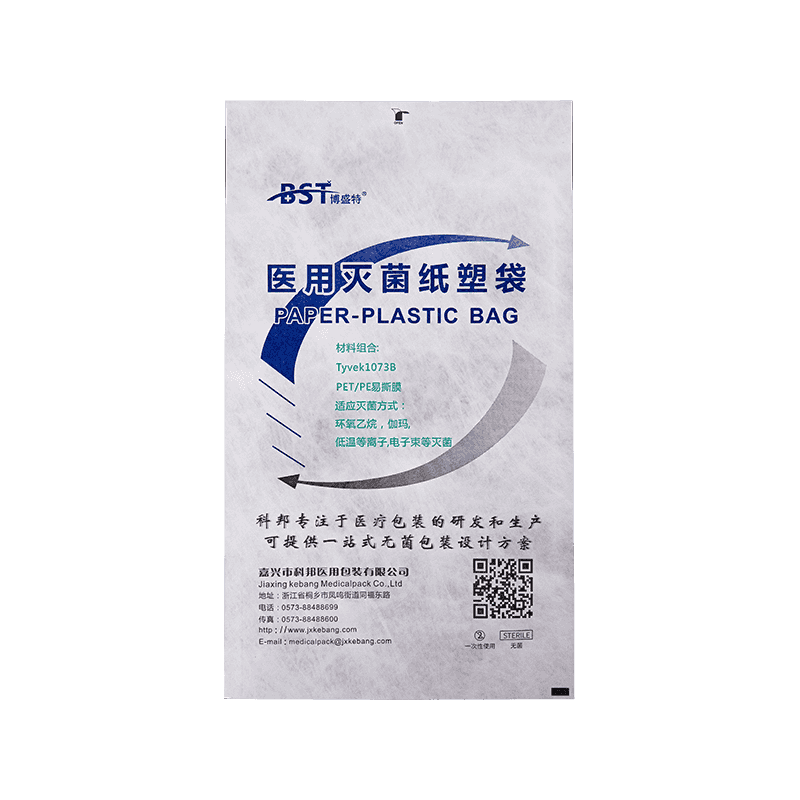

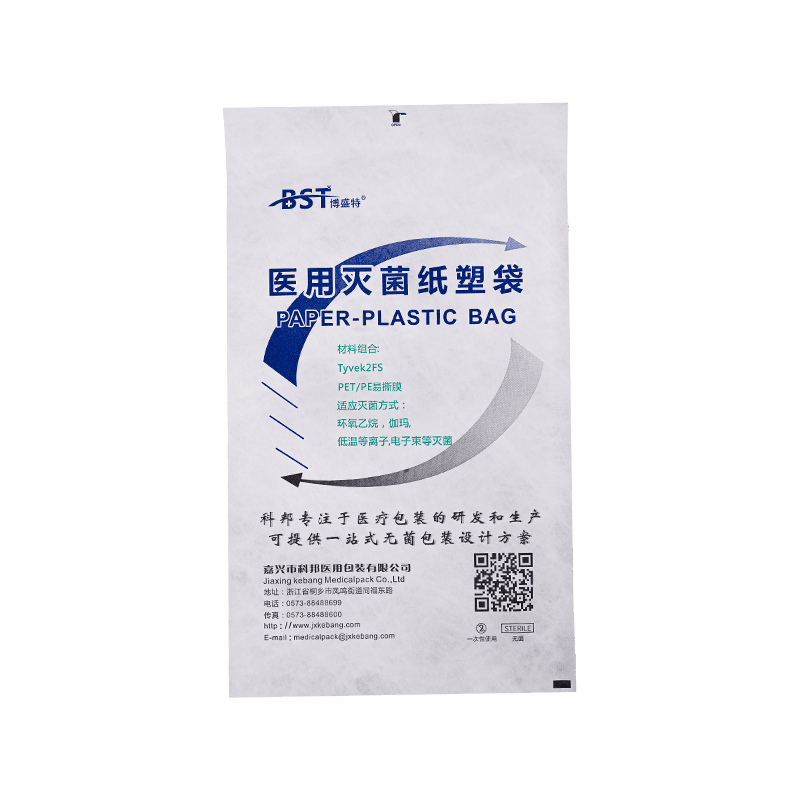

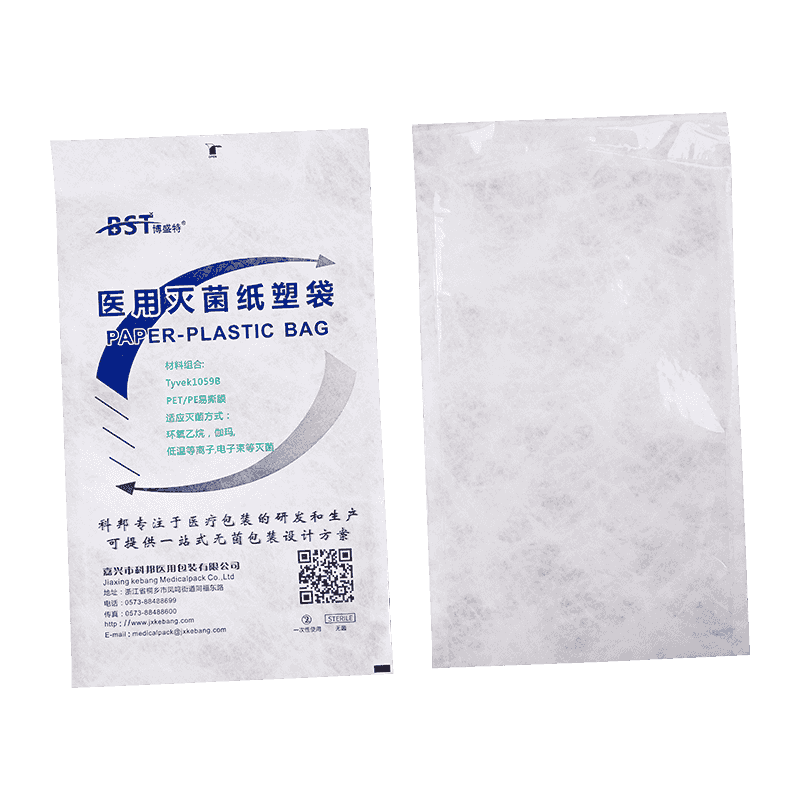

C

Material composition: Tyvek1073B, 1059B, 2FS base paper + PET/PE easy-tear composite film

Features:

1. Good antibacterial properties and breathability

2. Excellent puncture resistance and water blocking properties

3. It has good heat sealing and peeling performance, making it easy to take out and use the instrument;

4. Printed with Tyvek’s special environmentally friendly water-based ink, which is non-toxic and has strong ink adhesion.

5. The product is valid for 5 years after sterilization

Sterilization form: suitable for ethylene oxide, irradiation, low-temperature plasma, electron beam, etc. Sterilization

Implementation standards: ISO 11607, EN 868, YY/T 0698-9

Applicable: Implantable medical devices: packaging of various disposable medical devices such as intraocular lenses, orthopedic repair equipment, sutures, surgical kits, infusion pumps, catheters, etc.

Product specifications: Can be customized according to customer requirements

Product Details

Message

Jiaxing Kebang Medical Packing Co., Ltd.

We have been selected as partners by a number of renowned brands and look forward to joining you.

Founded in 2013, Jiaxing Kebang Medical Packing Co., Ltd. is a China OEM Medical Paper-Film Pouch Suppliers and Custom Medical Paper-Film Pouch Factory, Sterilization Medical Paper-Film Pouch Suppliers, is a comprehensive medical sterilization packaging manufacturer integrating research and development, production and sales company. The company is located at 888 Safety Road, Lamb Industrial Park, Shimen Town, Tongxiang City, Zhejiang Province, in the core areas of Jiangsu, Zhejiang and Shanghai, with a beautiful factory environment and convenient transportation.

The company covers an area of more than 30 acres with over 25,000 square meters of plant area. We have been certified as an ISO13485 medical device quality management system, with a disinfection product production enterprise health license. According to the requirements of ISO11607 standard, we have built a total of more than 3,000 square meters of 100,000 level GMP, 10,000 level workshops, and 100 level product laboratories, physical testing rooms and biological laboratories. We also have passed the inspection and acceptance test of the Center for Medical Device Quality Supervision and Inspection (Hangzhou, Zhejiang Province) to meet the requirements of different customers on product quality and environment.

The company has dozens of domestic advanced production equipment such as high-speed printing machines, bag-making machines, solvent-free film composites machines, paper-coating machines, online die-cutting machines, slitting machines, digital cutting machines and numerous product lines. To ensure the continued stability of product quality, we have purchased product online testing systems, ethylene oxide sterilizers, high-temperature vapor sterilizers, tension detectors, paper permeability tester, ultraviolet analyzers, heat-sealing testers, particle detectors, bacterial incubators and various other testing equipment. The company's existing plant and equipment design is expected to reach an annual output value of more than 200 million yuan, with a daily capacity of 5 million sterilization packaging bags. In addition, our products are available in a variety and wide range of coverage and are used in a variety of sterilizing packaging products for Class I, Class II and Class III medical devices and medical facilities. With more than 20 years of experience as a medical packaging technician, the company can develop, design and customize one-stop packaging solutions to fully meet the needs of its customers. Since its founding, the company has maintained a focus on professionalism, dedication and continuous improvement of the company's faith, serving nearly 300 domestic and foreign customers, with products exported to more than 100 countries. At the same time, the company has paid attention to personnel training and product production technology research and development, and has been awarded more than 20 patents for inventions and utility models in a row, as well as the title of a national high-tech enterprise. We believe that Kebang, with its professionalism, focus, hard work and effort, will be your trusted friend.

News

-

How can aluminum foil composite film rolls promote green tra...

1. Resource recycling: Building a green recycling system for the pharmaceutical industry(I) The recy...

View More -

Will medical aluminum-plastic composite film become history?...

1. The cursed golden triangleIn the medical packaging industry, there is a devil equation that has l...

View More -

Why is the medical paper film bag the invisible guard behind...

In the medical field, every detail related to the patient's health cannot be ignored. From large med...

View More -

How to keep medical devices sterile? Sterilization packaging...

1. The core role of sterilization packaging of medical devices: reducing hospital infections and imp...

View More -

Medical Blister Box Lid Packaging——A New Benchmark for Drug ...

In the medical field, the storage and distribution of drugs are crucial and directly related to the ...

View More -

Medical Packaging Innovation: Medical Paper Film Pouch Impro...

1. Material Selection and PerformanceMedical Paper Film Pouch is usually made of high-quality medica...

View More

English

English 中文简体

中文简体